At every stage... we're looking for a better way!

We sign mutual Non Disclosure Agreements and you brief us on your innovation.

Our engineers develop the fullest potential of your idea and our composite fibre expertise to comply with all relevant regulations and standards.

After discussion and agreement the design work is handed over to our very experienced team of composite fibre manufacturing experts.

We develop plugs using our state of the art CNC 3D Routers. These are now 'virtual products' for you to see and touch for approval.

You signoff on the engineering designs and product prototypes ready for handover to our production floor.

Your approved design is rapidly prototyped for your approval. It's then submitted for engineering testing.

Skilled Craftsmen apply decades of finely honed workflows to deliver the fullest potential.

Random QA Measurements are carried out during the manufacturing process to ensure your product is true to specification.

Your order is shipped in bulk to your warehuse or direct drop shipped by special arrangement.

Testing:

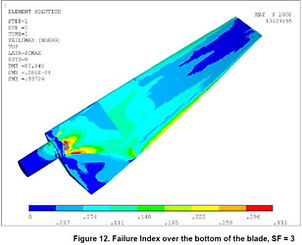

Finite Element Analysis (FEA) and Testing

BAC views FEA (Finite Element Analysis) as a vital tool in engineering design and manufacture. By undertaking FEA the laminate arrangements, materials, and geometry of a component can be optimised to ensure it operates and performs at its very best.

The capacity to conduct load testing on composite prototypes provides confirmation that the final design is suitable for its intended purpose.

BAC have and continue to work closely with staff from the University of Southern Queensland's (USQ) Centre for Excellence in Engineered Fibre Composites (CEEFC) to deliver independently certified, load tested products.